What Are the Main Structures of an Energy Storage Container?

by

What Are the Main Structures of an Energy Storage Container?

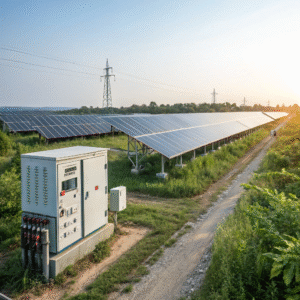

Energy storage containers are revolutionizing how we store and deploy power, but what exactly makes up these innovative systems?

The main structures of an energy storage container include the battery rack system, battery management system (BMS), thermal management system, power conversion system (PCS), fire suppression system, and structural enclosure - all working together to safely store and deliver energy.

These modular powerhouses combine multiple critical systems within a standardized shipping container design, creating a plug-and-play solution for energy storage needs. Let's examine the key components that make these systems work.

How Does the Battery Management System (BMS) Monitor Battery Status?

Ever wondered how energy storage systems keep track of hundreds of battery cells simultaneously? The secret lies in advanced monitoring technology.

The BMS continuously monitors each battery cell's voltage, temperature, state of charge (SOC), state of health (SOH), and current flow using networked sensors, ensuring optimal performance and safety throughout the system's lifespan.

Comprehensive Monitoring Capabilities

| Parameter | Monitoring Method | Purpose | Alert Thresholds |

|---|---|---|---|

| Voltage | Individual cell measurement | Prevent over/under charging | ±5% of nominal |

| Temperature | Thermal sensors per module | Prevent thermal runaway | >45°C warning, >60°C shutdown |

| SOC | Coulomb counting + voltage correlation | Accurate charge level | <20% or >90% capacity alerts |

| SOH | Cycle counting + impedance testing | Predict remaining lifespan | <80% original capacity warning |

Advanced BMS features:

- Real-time data logging for performance analysis

- Automatic cell balancing to equalize charges

- Predictive maintenance alerts

- Redundant safety monitoring circuits

Does the Energy Storage Container Have Emergency Shutdown Mechanisms?

When dealing with megawatt-scale energy storage, safety systems can't be an afterthought. How do these containers handle emergencies?

Energy storage containers feature multi-layer emergency shutdown systems including circuit breakers, contactors, and pyrofuses that can isolate the battery pack in milliseconds when faults are detected.

[image placeholder: Emergency stop button and shutdown components in storage container]

Emergency Shutdown Hierarchy

-

Primary Protection (ms response)

- Pyrofuses: Explosive disconnect for immediate current interruption

- Main contactor: Breaks DC circuit

- AC breaker: Isolates from grid

-

Secondary Protection (seconds response)

- Battery string fuses

- Thermal runaway containment

-

Tertiary Protection (minutes response)

- Fire suppression system activation

- Ventilation shutdown

- Remote monitoring alerts

How Are Energy Storage Containers Protected Against Fire and Earthquakes?

Storing massive amounts of energy inherently carries risks - what protection measures are built into these containers?

Energy storage containers incorporate fire-resistant materials, seismic bracing, gas detection systems, and thermal runaway containment to meet stringent UL9540A and IEC62619 safety standards for fire and earthquake resistance.

Comprehensive Safety Systems

| Hazard | Protection Method | Standard Compliance |

|---|---|---|

| Fire | - Aerosol suppression systems - Thermal barriers - Flame retardant materials | UL9540A fire test |

| Earthquake | - Seismic bracing - Vibration isolation - Structural reinforcement | IBC seismic zone 4 |

| Explosion | - Pressure vents - Gas detection - Spark-proof components | ATEX certification |

| Environmental | - IP55 rating - Climate control - Corrosion protection | NEMA 3R equivalent |

Key safety features:

- 1-hour fire rating enclosure

- Seismic certification for high-risk zones

- Continuous gas monitoring

- Remote emergency power-off capability

Conclusion

Modern energy storage containers integrate advanced monitoring, multi-layer safety systems, and robust structural designs to provide safe, reliable energy storage solutions for diverse applications and environments.